Market Overview:

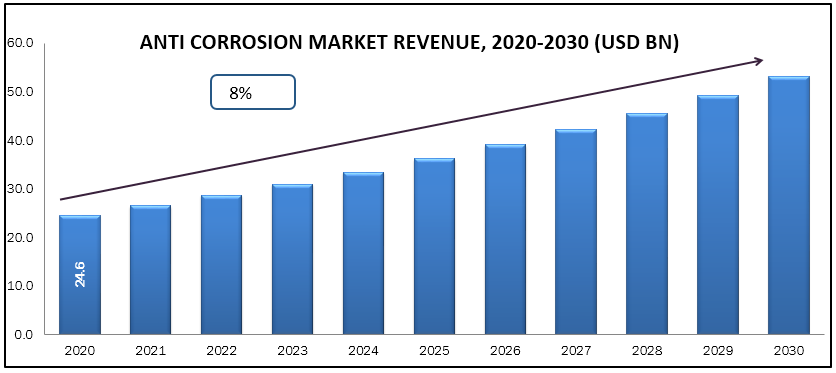

Corrosion is the surface deterioration of metal within particular environment because of oxidation, moisture, salt spray etc. Anti- corrosion coating prevent the corrosion of metal by acting as a barrier between corrosive material and that metal. These coating are highly use for enhancing the sheet life and its usage. These sheet utilized by various industry ranging from marine oil & gas, industrial power generation, automotive and others. It is mostly use in shipbuilding and construction industry and its raw materials are derived from petroleum. The Global Anti-corrosion Coating market size is estimated to be USD 24.6 billion in 2020 and anticipated to reach USD 53.2 billion, at a CAGR OF 8.0%.

Market Segmentation:

On the basis of type the anti-corrosion coating market is categorized into epoxy, polyurethane, acrylic, alkyd, zinc, chlorinated rubber, and others. On the technology basis market is segmented into solvent borne, waterborne, power coating, and others. On the basis of end user industry market is divided into marine, oil and gas, industrial, automotive, construction, energy, and others. By geography, anti-corrosion coating market is segmented into Asia Pacific, North America, Europe, and rest of the world.

Market Dynamics and Factors:

Rising loss due to corrosion in ship building, construction, and other industry is one of the most significant factor to increase growth of the anti-corrosion coating market. Rise in the power generation and transportation & automotive industries, is the major driving factor for the anticorrosion market. End user of anti-corrosion coating prefer those product that provide chemical, water, acid, hydrocarbon resistance improve productivity and increase the service of the component and reduced the maintenance cost are the factor that help anti-corrosion coating market growth. The fluctuating raw material cost is one of the major factor that hammer the anti-corrosion coating market growth. A majority of raw material use to production of anti-corrosion coating are extract from petroleum. The shipbuilding industry is highly concentrated as that market has opportunity to make high performance and auto corrective anti-corrosion coating.

Geographic Analysis:

Asia Pacific dominates the anti-corrosion coating market due to the number of end use industries as the growth in the region. In Asia Pacific, through Japan, China and South Korea lead the shipbuilding industry and new ship building hubs are appearing in Vietnam, India, which helps the anti-corrosion market to grow. Asia Pacific is the leading importer and exporter of crude oil and crude oil is a main ingredient to make anti-corrosion coating. Europe is also emerging as strategic locations for anti-corrosion coating market after Asia Pacific. As increase investment in the construction and ship building industry in the region. It increase at a CAGR of 6.2% in forecast period. LAMEA is anticipated to grow with the CAGR of 6.0% in forecast period. As increase investment in shipbuilding industry in the region.

Competitive Scenario:

The key players operating in the anti-corrosion coating industry are 3M Co., AkzoNobel N.V., BASF SE, Hempel A/S, Akzonoble N.V., Kansai Paints Co., Ltd, Nippon Paints Co. Ltd., PPG Industries, Inc., The Sherwin-Williams Company, Axalta Coating Systems Ltd., The Dow Chemical Company, and Wacker Chemie AG.